实时成像,是一种X射线无损检测方法。是通过屏幕实时显示检测结果图像的方法,利用该图像对检测对象材料进行定性、定量的分析、判断和评估,从而获得检测对象材料的均匀性和一致性,或对象结构、装配、材料密度、厚度等信息,达到无损检测的目的。实时成像方法因其检测图像直观清晰、检测速度快和成本低的优势,受到业界高度的关注和日新月异地高速发展。在早期因得到的图像为模拟图像,因此称其为实时成像,也被称做工业电视。随着数字技术尤其是数字图像技术的迅猛发展,实时成像更向数字化方向发展的趋势,越来越多地被称为数字成像。

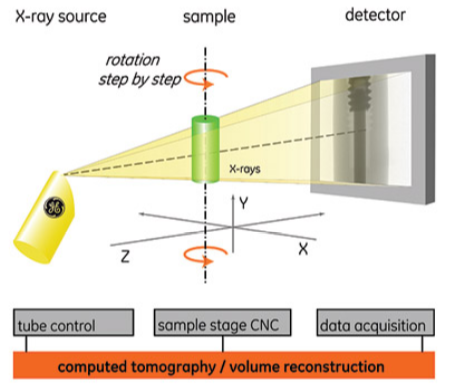

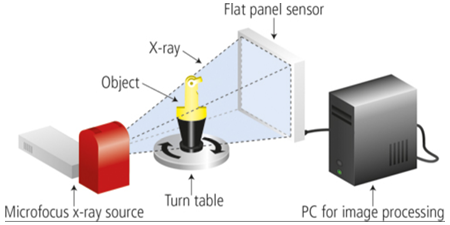

实时成像无损检测方法,以其直观和高品质的检测效果、高效率、低成本的检测等优势,受到国内外业界的高度重视,成为射线无损检测的发展方向,逐步取代胶片成像的趋势。目前欧美等发达国家采用实时成像系统占整个射线检测领域的份额比较高,并呈现快速增长的态势。国内随着人们认识水品的提高,技术手段的日益完善、技术标准的不断跟进,实时成像系统近年来取得了突飞猛进的发展,受到越来越多的企业、科研院所等单位的青睐,并从中受惠。实时成像方法与传统的胶片成像相比较,对缺陷的可识别性更高;检测成本低;检测效率提高十倍以上;通常一或二位操作人员即可胜任设备的操作;因快速高效检测的特点,扩大产品的检测范围成为可能,进而提高了产品的质量;系统因为不产生任何污染环境的排放,符合绿色环保的要求。尽管该系统的造价稍贵,但与胶片检测相比较,在大批量检测的场合,一年内收回全部设备成本是完全可能的。为企业降低生产成本,提高产品质量,加快交货速度提供了设备保证,从而从根本上提高企业的市场竞争力。同传统胶片照相法相比,实时成像的检测原理有很大的不同。传统照相法是将穿过工件的X射线在胶片上累计感光而形成潜影图像,再经暗室处理形成可见的透照影像,根据其影像来评估工件的内部质量情况,得到的图像是静态影像,是不可调整的。实时成像系统是将穿过工件的X射线经图像探测器接收并转换为数字图像信号(早期有模拟信号),经计算机系统的处理,显示或保存该数字图像,在此成像的过程中,图像的亮度、对比度、清晰度等受射线的电压、电流、工件的位置、透照工艺等参数变化而有所不同,并实时反馈在显示器屏幕上表现出来,所调即所得。实时成像的检测效率和速度,更多地受配套的机械传动部分的影响最大,成熟可靠的机械传动和控制能为最大限度地发挥成像部分的性能至关重要,是高效检测的重要影响因素之一。完备简单的自动控制方法,在确保图像质量的一致性,可高效可靠检测过程中比不可少的。

Computed radiography (CR) is the digital replacement of conventional X-ray film radiography and offers enormous advantages for inspection tasks – the use of consumables is virtually eliminated and the time to produce an image is drastically shortened.

In computed radiography, when imaging plates are exposed to X-rays or gamma rays, the energy of the incoming radiation is stored in a special phosphor layer. A specialized machine known as a scanner is then used to read out the latent image from the plate by stimulating it with a very finely focused laser beam. When stimulated, the plate emits blue light with intensity proportional to the amount of radiation received during the exposure. The light is then detected by a highly sensitive analog device known as a photomultiplier (PMT) and converted to a digital signal using an analog-to-digital converter (ADC). The generated digital X-ray image can then be viewed on a computer monitor and evaluated. After an imaging plate is read, it is erased by a high-intensity light source and can immediately be re-used – imaging plates can typically be used up to 1000 times or more depending on the application.The CR have below advantage: Cost-effective solution for upgrading old X-ray equipment.No silver-based film or chemicals are required to process films.Reduced film storage costs, as the images are stored digitally.Image brightness and contrast can be adjusted after the exposure.Image can be processed and enhanced at any time after the exposure.

鲁公网安备 37020602000203号

鲁公网安备 37020602000203号