目视检查是无损检测中重要的一种方式,其有效性以及经济型使目视检测越来越广泛的应用。它要求检验工程师具备以下能力:

- 图纸标准的掌握

- 整体生产工艺技术质量的掌握

- 相关文件的掌握

目视检测条件满足以下内容:

- 推荐光照强度不低于1000Lux。

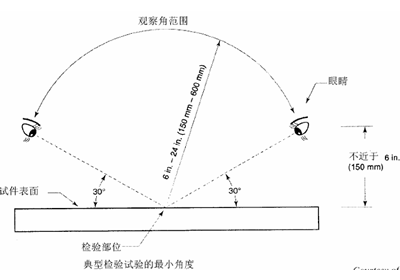

- 检验人员眼睛距离检查表面的距离在300-600mm之间。

所使用的辅助检验工具有:

- 焊接检验尺

- 间隙尺

- 错边尺

- 放大镜(2-5倍)

- 内窥镜

Visual examination of weld joint is an important activity, carried out to check the integrity and soundness of the weldment. It is an economical activity, as it doesn’t require any costly equipment. It must be carried out by a well experienced inspector.

The Visual test required experienced engineer as below scope:

1. Drawing Code compliance

2. Overall Workmanship

3. Relatived Documentation Control

he requirements of visual examination are:

1.It is recommended to carry out visual inspection at an illumination of more than 1000 Lux.

2.The inspectors eye should be within the radii of 600 mm of the surface of item being inspected and the viewing angle must not be less than 300.

Other aids which may be required during visual examination are:

1. Welding gauges

2. Weld gap gauges

3. Linear misalignment gauges (Hi-Low)

4. Magnifying glass (X2 to X5)

5. Mirrored boroscope or fibre optic viewing system (when access is restricted)

鲁公网安备 37020602000203号

鲁公网安备 37020602000203号